About us

Avery Instrument Limited is offering sensor products for high performance, harsh and extreme environments.

The product lines include pressure sensors, transducers and related instruments to monitor pressure, differential pressure and liquid level.

Mission

Being sensor component partner that offers comprehensive solutions in close collaboration with our customers-customised and precisely designed products for the exact requirements!

Pressure, temperature and level measurement solutions from Avery Instrument Limited are integrated in various operation processes of our customers.

We consider ourselves not only supplier of measurement components but sensor component partner also.

Pressure Sensors

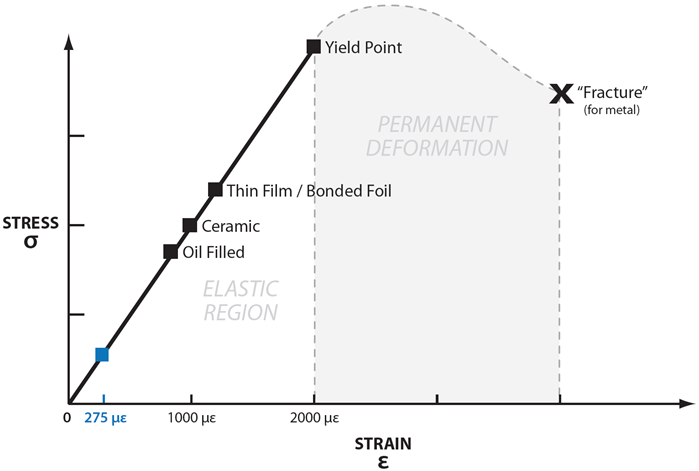

AVERY Instrument Limited manufactures pressure sensors in Asia headquarters from start to finish. Silicon strain gages are applied to the machined component made of 17-4 PH stainless steel, 316L stainless steel, Inconel 718, Hastelloy C276, or titanium, which completely isolates the liquid or gas to the sensor front end, eliminating welds and O-rings. Customers receive a robust, reliable and repeatable signal as a millivolt sensor or amplified pressure transducer.

AVERY Instrument Ltd. is now manufacturing an industrial / commercial line of standard and custom designed pressure sensors and transducers.

OEM

After the strain gages are applied to the diaphragm, AVERY completes the assembly process by adding electronics, housings and electrical connections to our standard products or customer specific designs. Pressure sensors, liquid level sensors, and differential pressure transducers are available for OEM equipment, yet have no minimum order quantity.

AVERY Instrument Ltd. superior sensor technology and manufacturing capabilities make us the perfect partner for OEMs looking to create innovative new products with industrial or consumer applications. In addition to our own brand-name lines, we design and manufacture products for some of the top names in the world.

Typical Industrial Applications

We can offer competitive flexible solutions to meet your sensor You will also see products from our range of sensor-based consumer products including tyre pressure gauges.

If you are interested in our Pressure Sensor products and would like to know more please contact us at email:

info@averyinstrument.com

Warranty

Workmanship - Avery Instrument Limited (AVERY) pressure sensors have a limited one-year warranty to the original purchaser. AVERY will replace or repair, free of charge, any defective sensor. This warranty does not apply to any units that have been modified; misused, neglected or installed where the application exceeds published ratings; the label getting lost, broken,or unrecognizable when return.

Installation/Applications - The purchaser is responsible for media compatibility, functional adequacy, and correct installation of the sensor.